TAPPICon 2024 Podcast

Herman explains ESKO’s commitment to service, design, sustainability and more!

Good to Know Flow Meter Facts

Some flow meter features can catch users by surprise. How many of these flow meter facts do you know already?

Floats and Tapers – why are some flow meters blinged out with red sapphire floats?

Float materials matter! Different flow liquids and gases need different floats and tube tapers to accommodate the flow media.

Flow meters vs. Winter

Extreme or prolonged cold weather can make maintaining process flows and accurate flow measurement challenging. Temperature drops not only affect viscosity of flow media but related metering components too: piping, fittings, and every component of a flow meter needs to be able to withstand freezing.

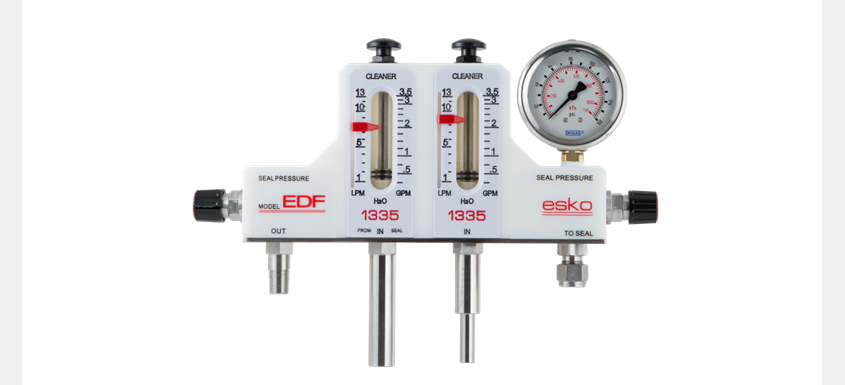

Seal Water Management Tips

Every ESKO seal water meter is meticulously assembled using stainless steel components and thermoplastic or borosilicate glass tube options that cover a wide range of operating conditions, temperature variations, and corrosive chemicals. Numerous O-ring choices cover a large variety of process conditions.

Flow Measurement Accessories & Add-ons

Fine tuning your flow monitoring?

What if process conditions change?

How to fine tune your flow monitoring installations with optional accessories and add-ons for additional operational and cost benefits.

Finding the Right Flow Meter – A Step by Step Approach

Flow meters are highly customizable due to differences in design, function, accuracy, and build components such as tube materials, end block materials, fittings, floats, valves, o-rings, flow configurations and more.

Grease Lubrication Best Practices

In addition to managing circulating lubricating oil, grease application is another important aspect of bearing and equipment maintenance.

Oil Lubrication Best Practices

Circulating oil lubrication systems are commonly used in pulp and paper manufacturing to support long-term performance of equipment.

ESKO Pacific adapts to the changes

Original article on Paper Advance “There is nothing permanent except change” wrote Heraclitus, an ancient Greek philosopher. This observation holds particularly true today…