PNEUMATIC 1:65 GREASE PUMP

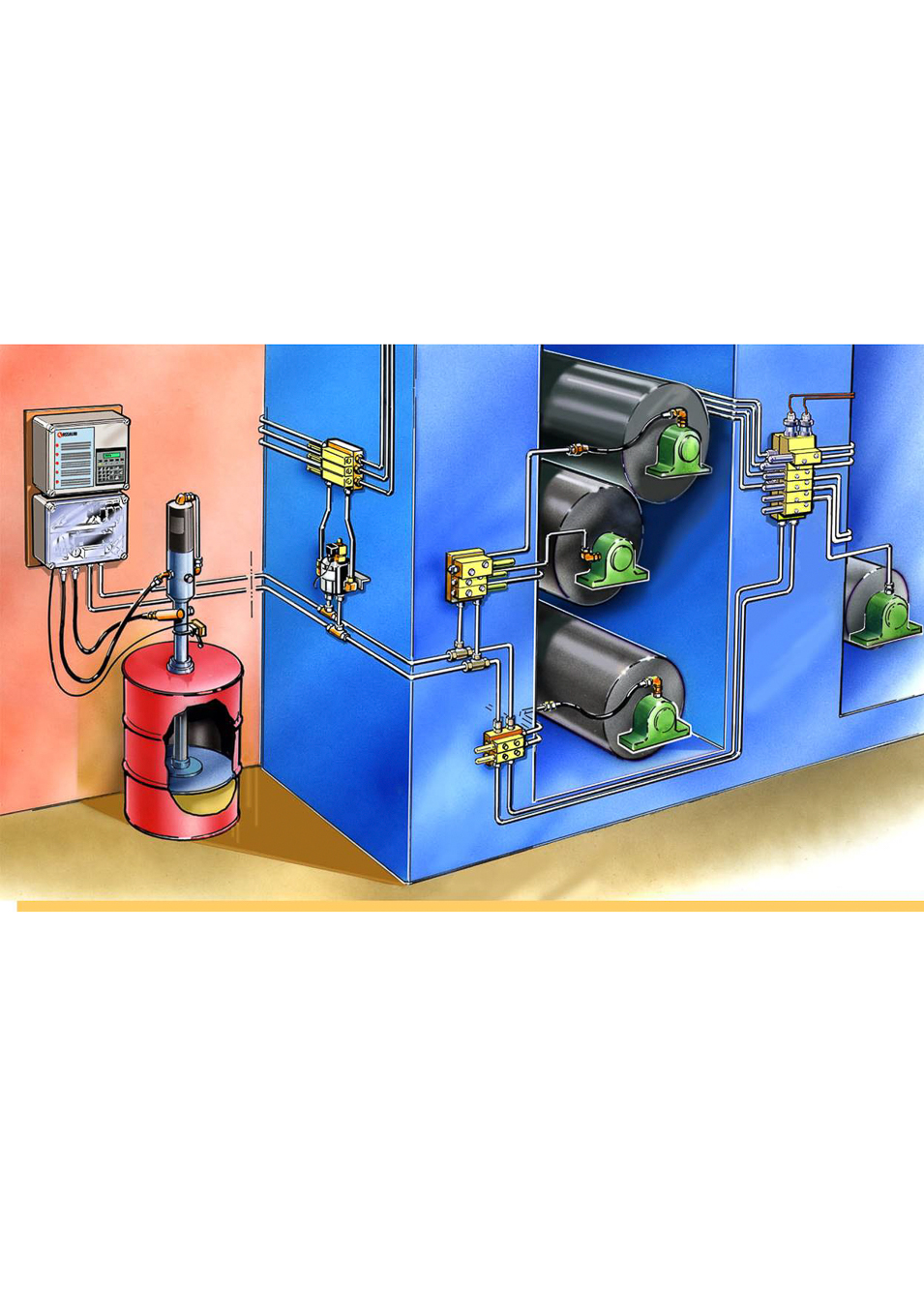

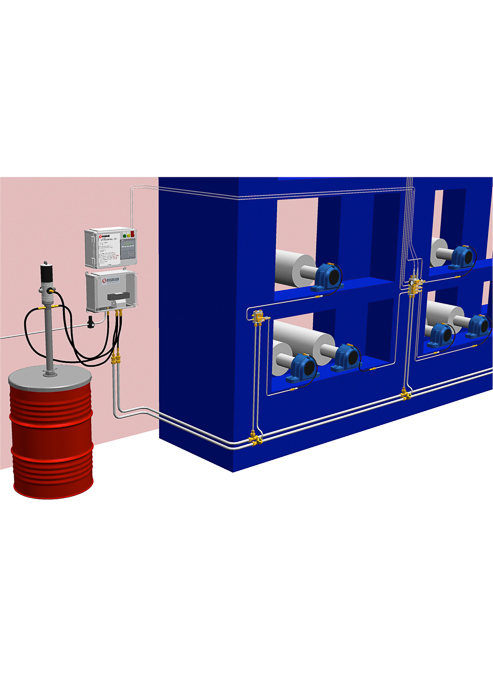

APPLICATIONS

- Virtually loss-free emptying of grease pails, kegs or drums using a reliable pneumatic pump

FEATURES

- Cost savings by ensuring that maximum volume of grease is dispensed

- Enviro-friendly – minimize wasted grease

- Pneumatic 1:65 pump generates ample delivery pressure for demanding applications

- Pump position gives clear and immediate indication of grease level in drum

OPTIONS

- Limit switch and holder for automatic or semi-automatic operation

CONVENTIONAL PUMPS LEAVE 10-20% OF THE GREASE BEHIND

AIR DRIVEN PUMP MECHANISM

THE TOTALLY EMPTIED CONCEPT

ASSALUB pumping innovation challenges conventional construction because the pump is supported on a floating follower plate. This follower plate/pump construction is designed as a completely closed grease handling system to empty a grease barrel. Only the grease remaining under the curved follower plate (about 2 kg in a 200 kg drum) is left in the barrel. The pump and follower plate fall with the grease level due to the weight and vibration caused by the pump, in combination with the vacuum that arises under the follower plate, preventing the plate from sticking in the drum. When the drum is empty, the follower plate rests hard against the bottom of the drum and is released by means of compressed air using an air gun (included).

TECHNICAL SPECIFICATIONS

| MODEL | PNEUMATIC 1:65 GREASE PUMP |

|---|---|

| MATERIALS | ANODIZED ALUMINUM, TEMPERED AND STAINLESS STEEL, BRASS AND PLASTIC |

| CAPACITY approx. | 2.65 lb/min (1,200 grams/min) |

| Grease outlet pressure | 7450 psi (520 bar) with 116 psi air supply |

| Grease outlet connection | 1/4″ NPT |

| Grease return inlet | Plugged tube fitting (12 mm) |

| Air supply pressure, min-max | 43.5 – 145 psi (3-10 bar) |

| Air supply connection | 1/4″ NPT |

| Pump tube diameter | 2″ (50 mm) |

| Optional accessories | Limit switch, limit switch holder for automatic or semi-automatic operation |